WS2 Dry Lube And The Pointers To Consider Before You Purchase Them

WS2 Dry Lube | Img Source : cdn11.bigcommerce.com

WS2 has proven to be a superior coating for bearings where conventional lubricants may be ineffective. It is required to be used in areas with high wear and tear, such as transmissions or gear boxes. Before purchasing WS2 dry lube online, keep in mind that the coating extends the shelf life. The coating of WS2 dry lube is known to enhance the service life of the fasteners in comparison to any other lubricant. It goes on to reduce noise or fiction and solves potentially a lot of issues at the same time.

The application process of WS2 Dry Lube

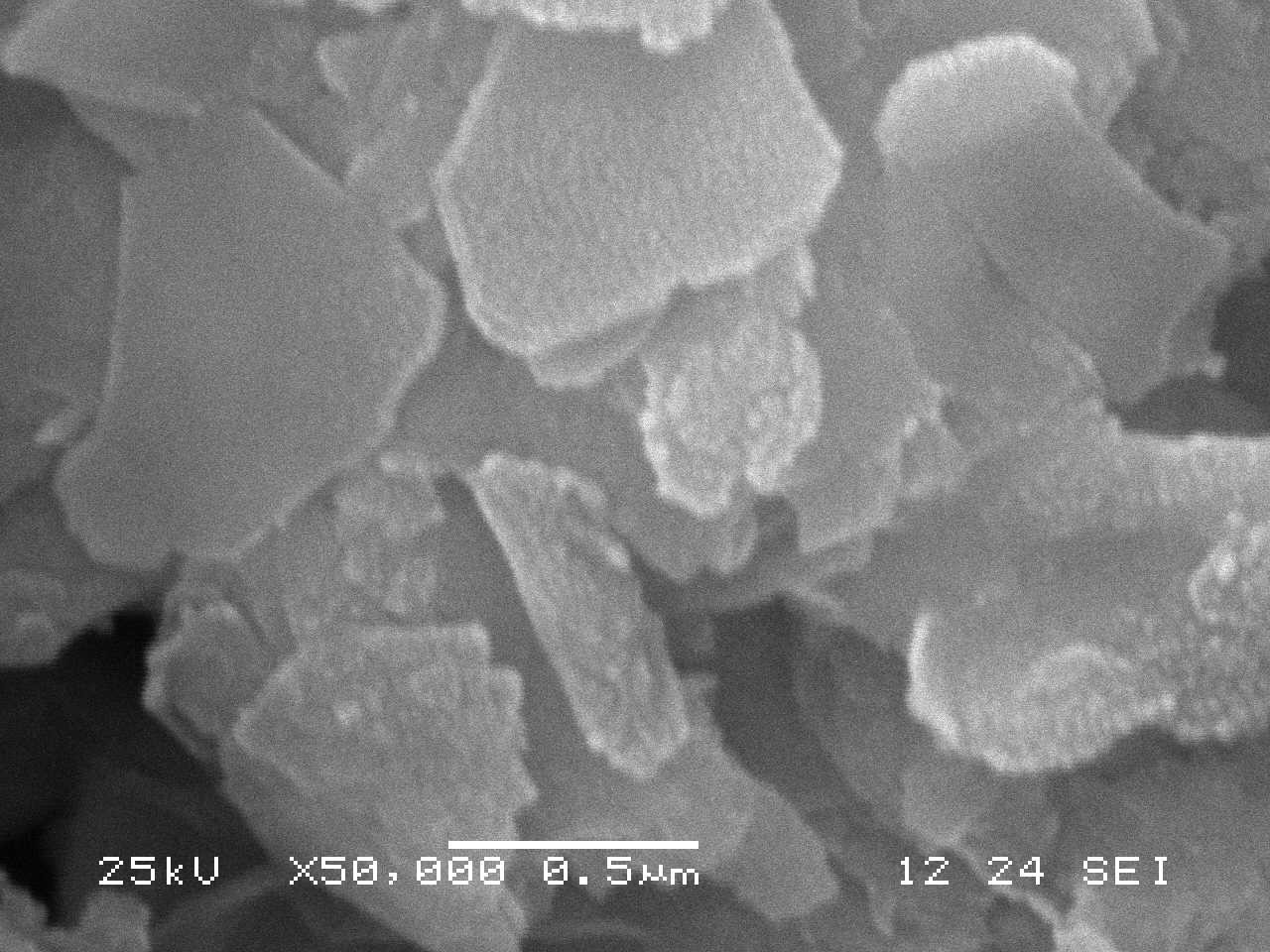

WS2 has historically been used on metal components as well as some non-metallic items in the form of thermosetting polymers. A thin coating of 12 micron thickness will be applied to help reduce friction levels. Online WS2 dry lube is compatible with metal components such as greases and hydraulic oil.

The raw material must be properly powdered and free of contaminants. It must be compatible with liquid oxygen systems as well as meet hard radiation requirements. Any components that need to be coated must be thoroughly cleaned prior to application. This would allow them to remove all external substances such as oil, grease, dirt, and any type of oxidation. It must be handled carefully to avoid re-contamination during the coating process.

Adhesion verification will validate WS 2, which relies on the use of pressure sensitive tape. This is directly applied to the sample and then removed in accordance. Furthermore, the thickness must be less than 0.0002 micron. The coatings must also withstand temperatures within a certain range. In terms of appearance, the coating film must be grey in colour and free of blisters, cracks, pin holes, and other surface imperfections. Finally, there is the quality aspect, which involves the inspection of the parts to ensure proper verification and adhesion. The coating must be smooth, uniform in colour, and free of surface imperfections.A large number of experiments were carried out, which resulted in resin improvements ranging from 2% to 5%.